Back-Ventilated Façade Systems (VHF): Energy Efficiency and Sustainability

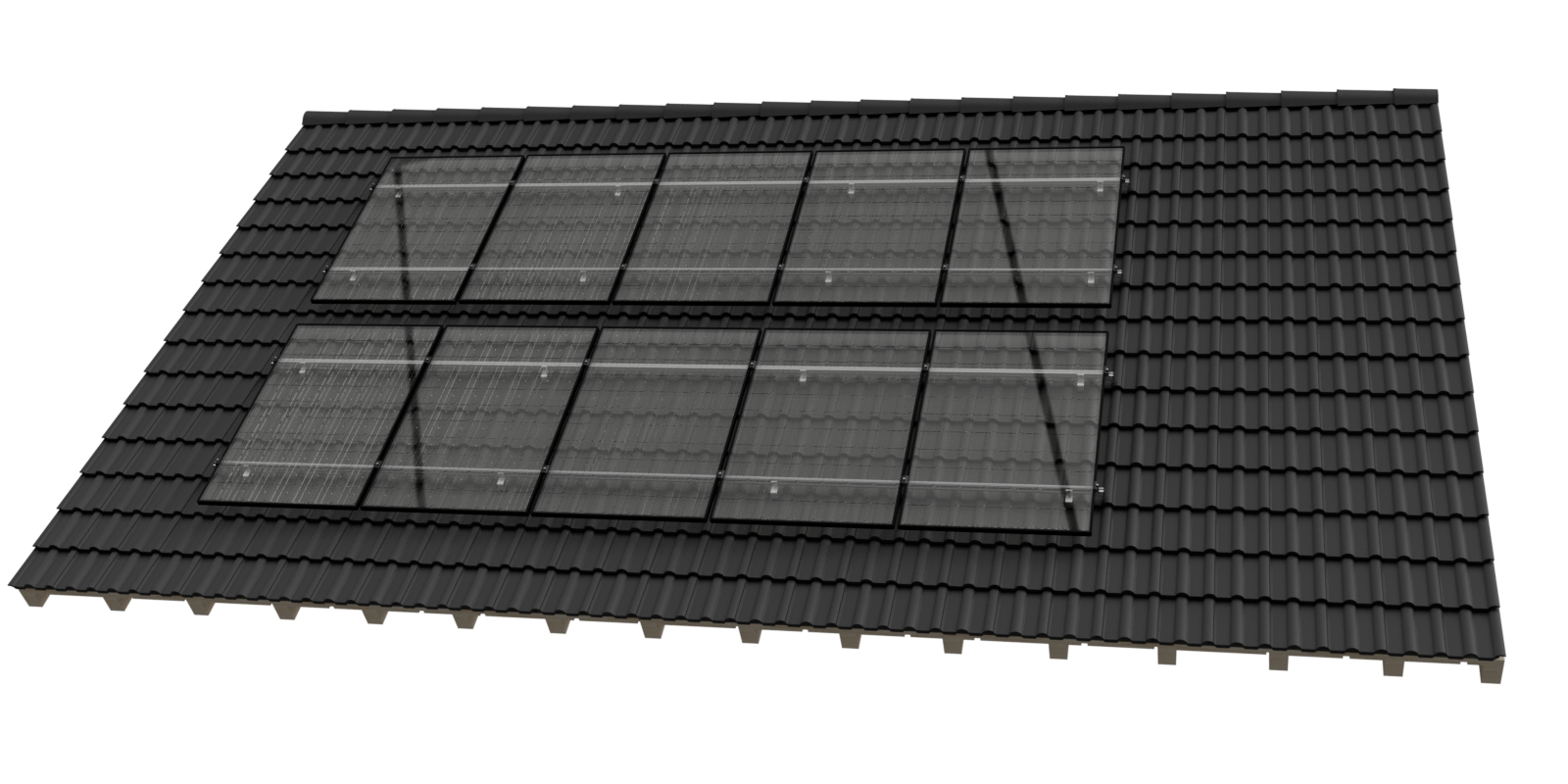

Back-ventilated façade systems (VHF) actively contribute energy efficiency of buildings by reducing heat loss in winter and preventing overheating in summer. The ventilation cavity ensures continuous moisture removal, protecting the building structure and extending its lifespan. By using sustainable and fully recyclable materials, our aluminum VHF system meets the highest environmental standards.

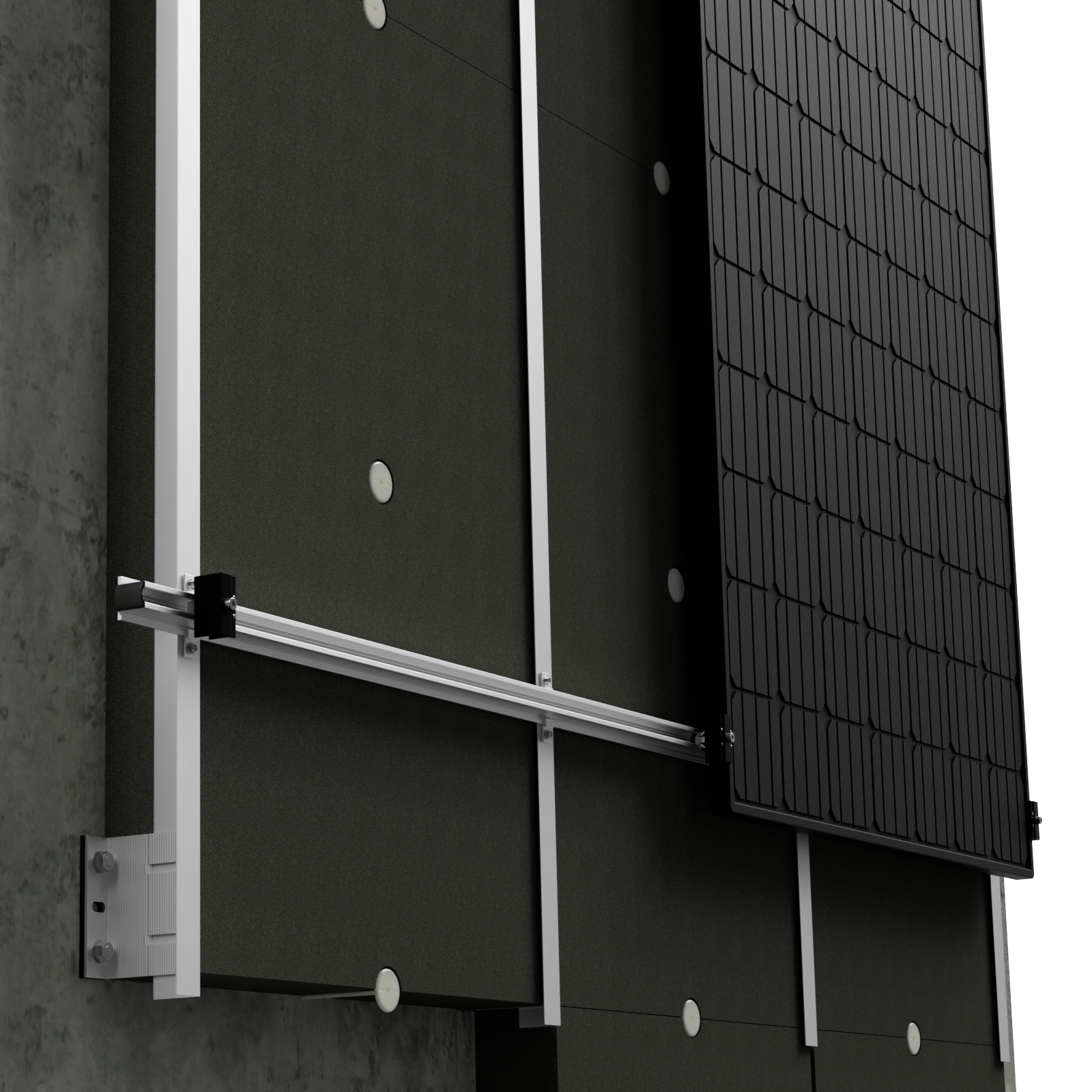

Advantages and Key Features of the ATPFix VHF Substructure:

Design Flexibility

The wide range of system components offered by the ATPFix substructure allows for virtually unlimited façade design possibilities with various cladding materials. This ensures that creative ideas and architectural requirements can be easily implemented.

Durability

The ATPFix substructure excels with extruded aluminum profiles and components, ensuring long-term resilience. Back-ventilated façades provide sustainable protection to the building structure and reduce maintenance needs in the long run.

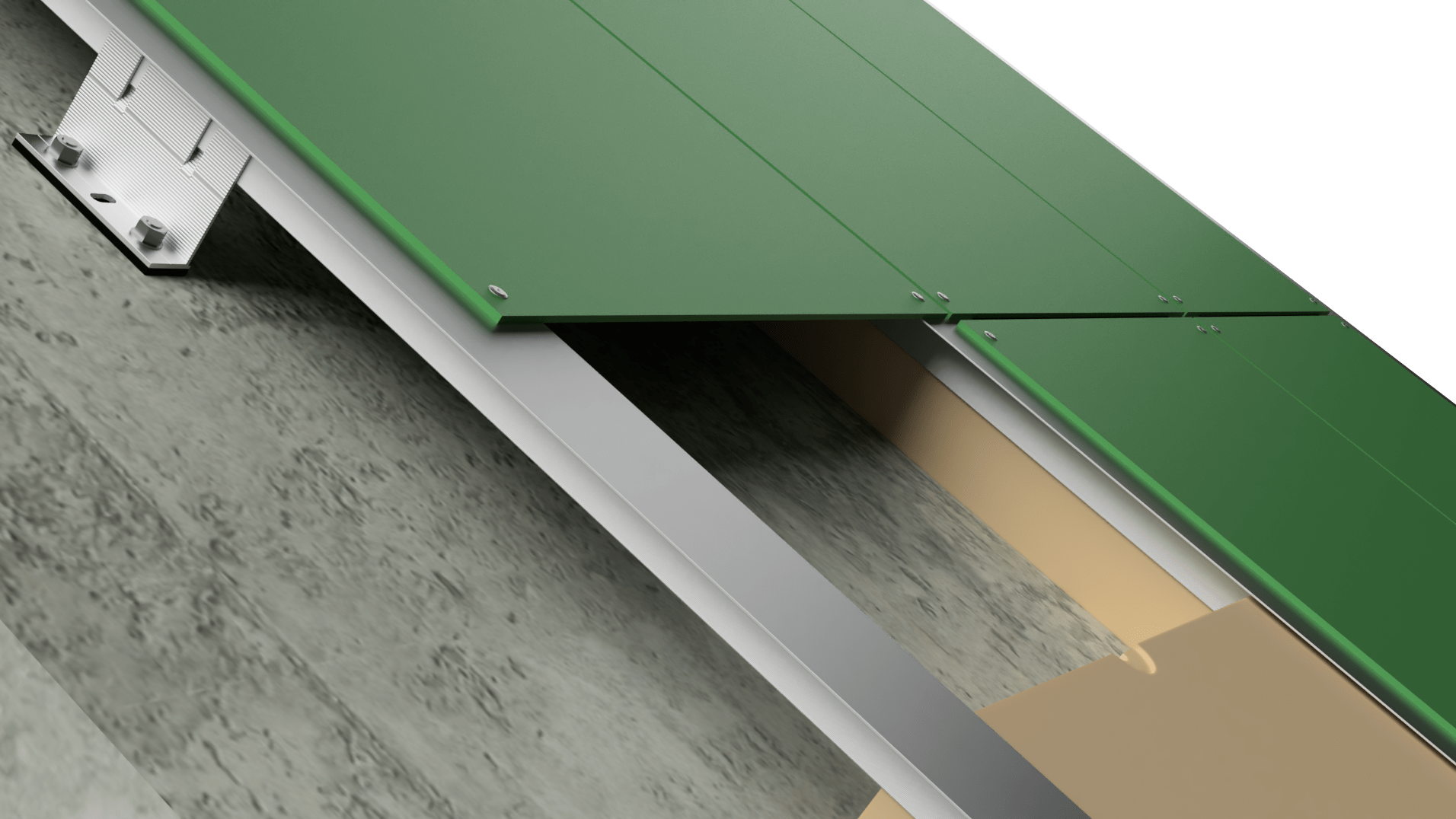

Thermal Insulation

The ATPFix system can accommodate differing energy requirements with custom-sized insulation. Thanks to adjustable wall spacers, virtually any desired insulation thickness is achievable. This flexibility ensures optimal temperature regulation and compliance with the latest energy efficiency standards by effectively mitigating summer heat and minimizing winter heat loss.

Ecology

Back-ventilated façade substructures support reduced energy consumption in both new construction and renovation projects. By improving heating energy efficiency, the carbon footprint (CO₂ emissions) of a building is measurably reduced.

Soundproofing

Back-ventilated façades equipped with the ATPFix substructure significantly reduce noise transmission through exterior walls. Depending on the thickness of the insulation, the weight of the cladding material, and the proportion of open joints, noise levels can be decreased by up to 14 dB – resulting in a noticeable improvement in living and working comfort.

Moisture and Condensation Protection

The construction principle of back-ventilated façades ensures a decreasing vapor diffusion resistance from the inside to the outside. The dew point is located in the ventilation cavity, keeping the insulation dry. The ventilation cavity reliably removes construction and usage-related moisture, providing long-term protection for the building structure.

Weather Protection

Façades are among the most vulnerable building components. Constant exposure to weather can cause moisture damage and cracks. The ATPFix VHF substructure enables a weather-tight façade compliant with DIN 4108-3, effectively protecting against moisture and weathering. The ventilation cavity between the insulation and cladding (weather protection) quickly removes moisture, making it possible to design back-ventilated façades with open horizontal joints without compromising weather resistance.

Recyclability of Components

The recyclability of building materials and components is a central aspect of sustainable construction and is becoming increasingly important. The aluminium substructure for VHF by ALU TP ensure that the components can be separated into their individual materials and returned to their respective recycling cycles.

Cost-Effectiveness

The use of the ATPFix system offers multiple advantages for investors. On the one hand, the ATPFix system enables the economical realization of VHF systems that improve a building's energy efficiency and reduce energy costs. On the other hand, the system facilitates the creation of aesthetically attractive buildings, ensuring their marketability and rental potential.

Fire Protection

The ATPFix system meets fire protection requirements in accordance with the selected façade components, fulfilling classifications such as "non-combustible" or "flame-retardant." This ensures the safe and regulation-compliant execution of your project.

The ATPFix substructure combines functionality, efficiency, and sustainability – delivering long-lasting façade solutions that meet the highest standards.